Photo Gallery

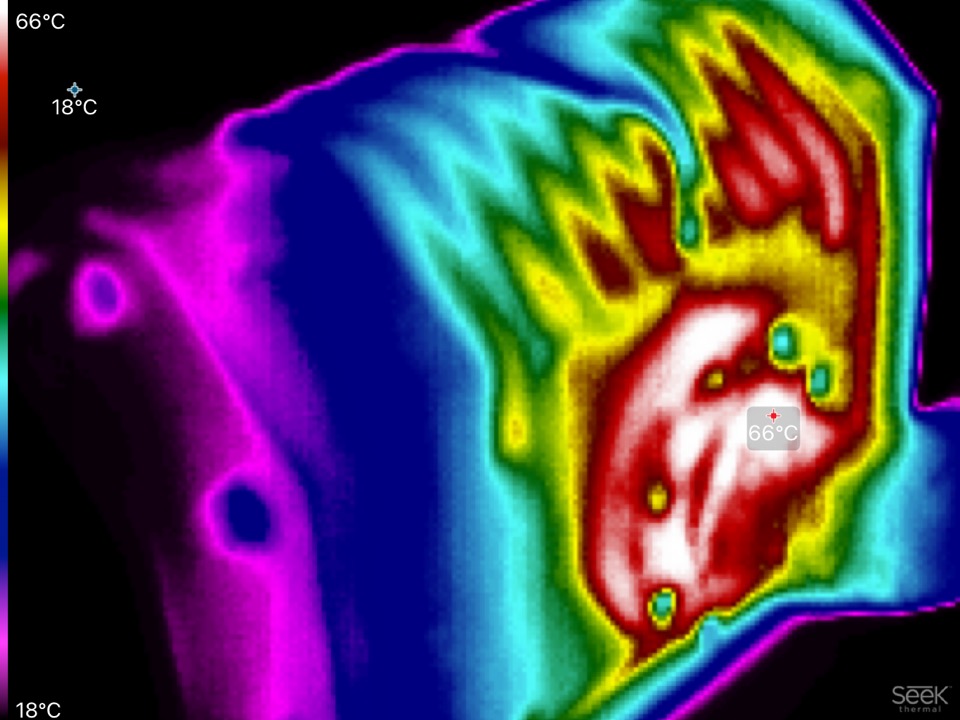

Thermal Diagnostics

By utilizing thermal cameras, we are able to quickly identify and address problems, ultimately reducing the risk of downtime and ensuring uninterrupted service. This picture shows a booster pump on a rotary vacuum machine - normal running temperature.

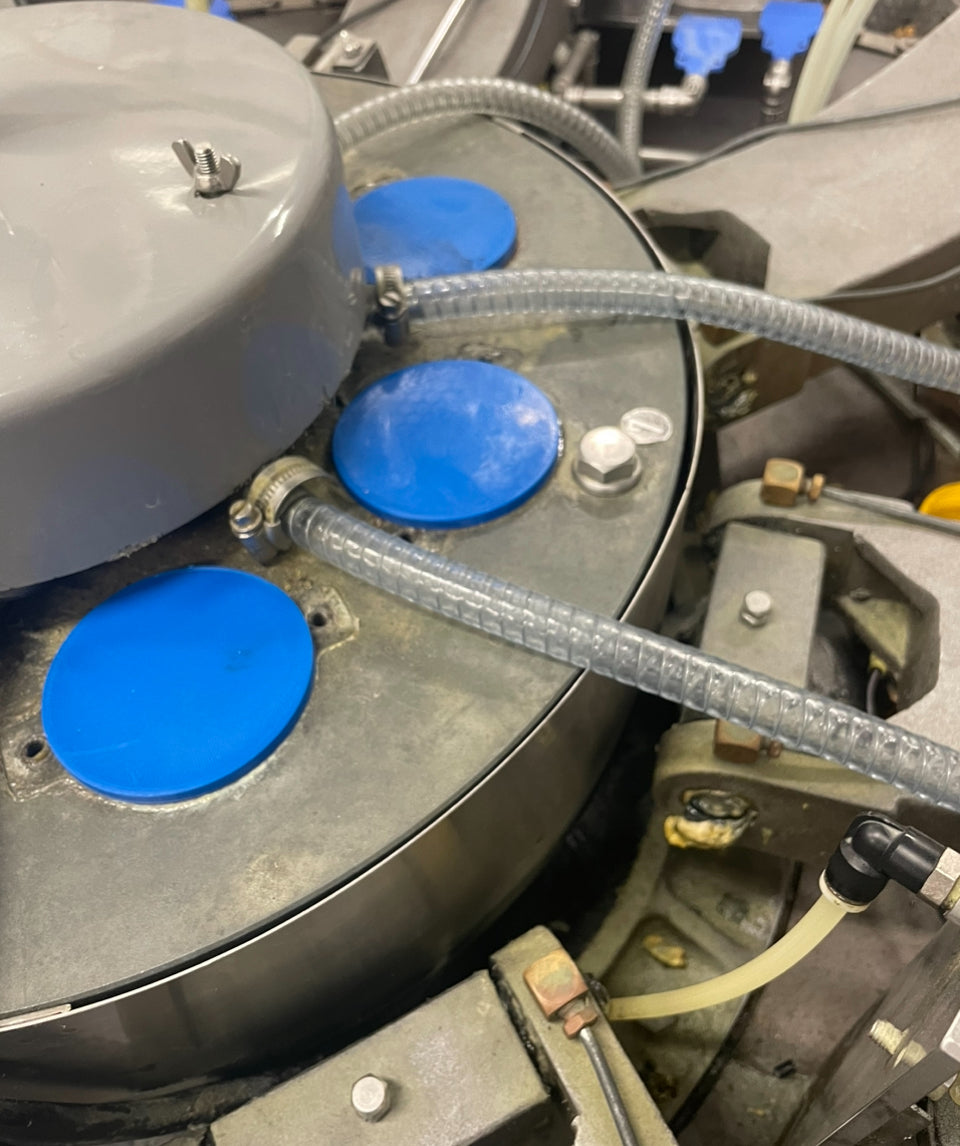

VR8600 machines

Upper slip ring assembly

New upper slip ring assembly, with carbon brush mounted at the back right.

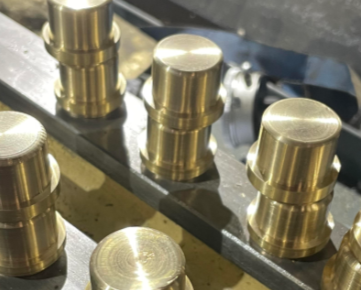

VR8600-14 machines

Main bearing

The main bearing of the VR8600-14 machine, shown after 3 years of hard work.

VR8600 machines

Vacuum port cover

It's happened....... the loss of a washer or bolt down into the second stage vacuum port could end up being expensive, if this ends up in the booster pump. Always cover the ports when removing the vacuum pipework and working around the valve.

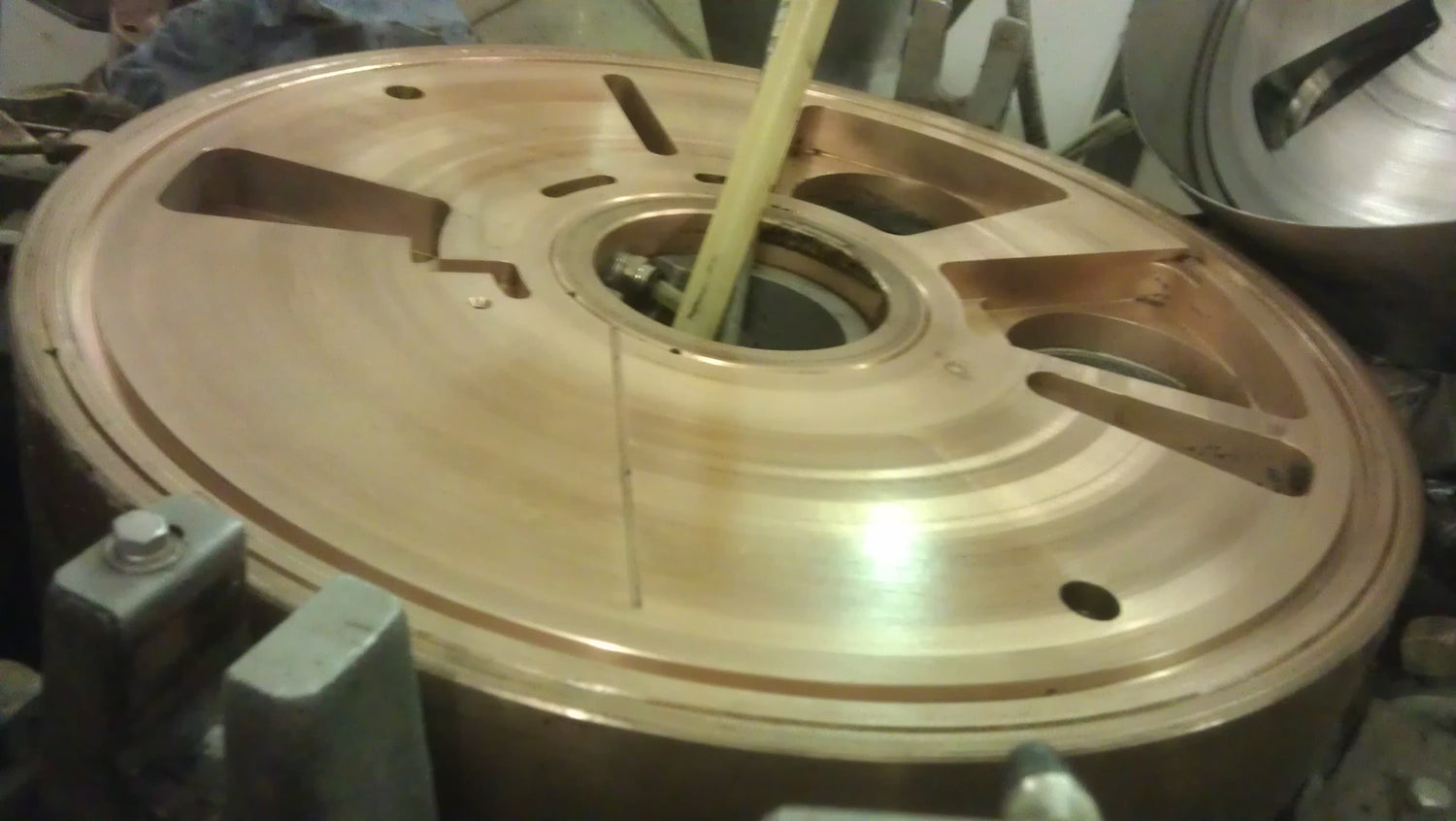

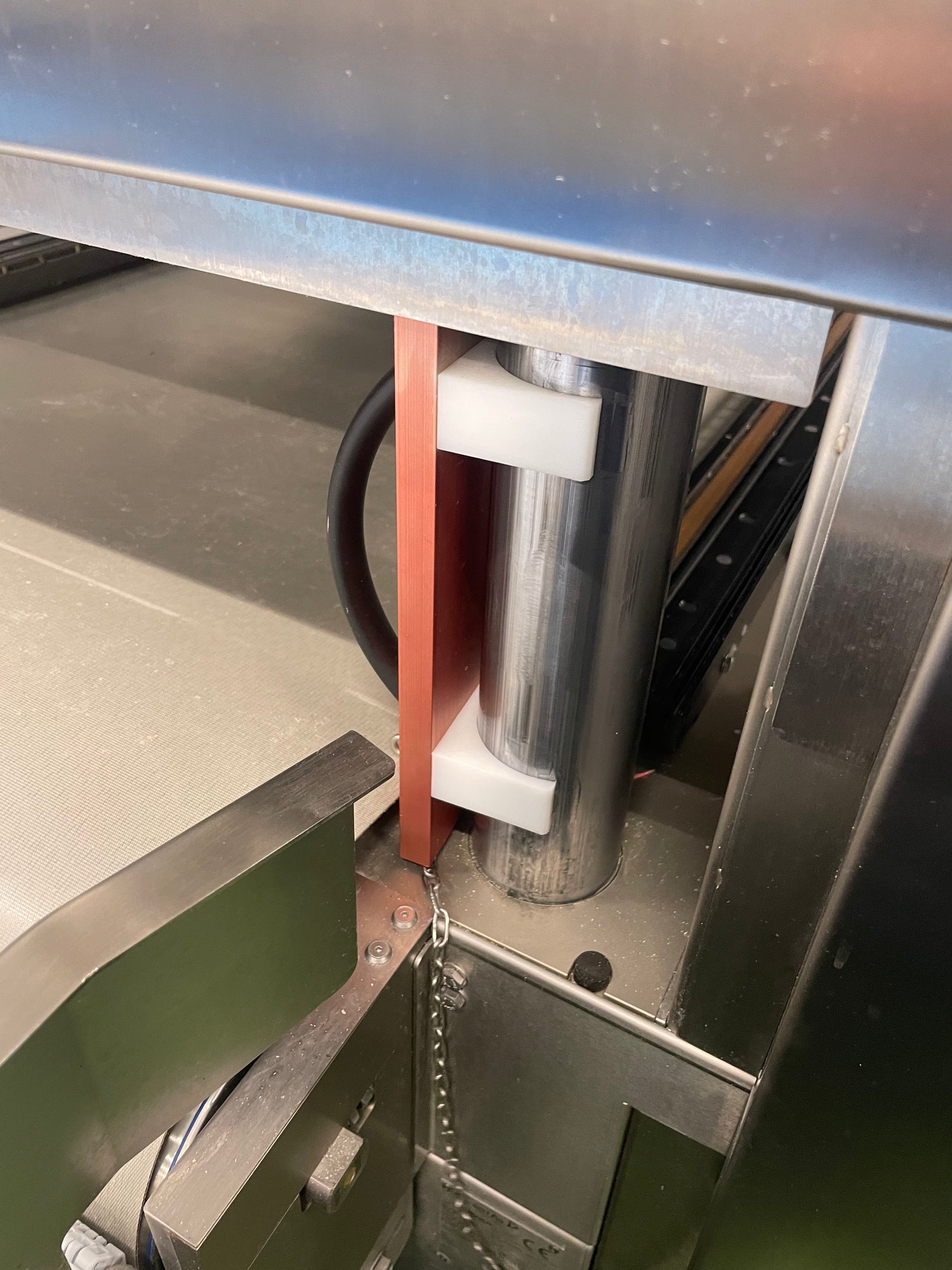

VR8600-14

Heavy work

Replacing the main bearing on a VR8600-14 would require the removal of the large sprocket. We undertake this work - a two day job.

VR range of machines

Vacuum Rotary Valve

Probably the most important (and expensive!) part of the machine. Facilitating the vacuum and sealing elements of the equipment.

VJ15

The old one!

Technologies change, but the principal of operation remains. Yes we work on these 30 year old machines. The principal of the moving parts are similar, just the design and technology have changed.

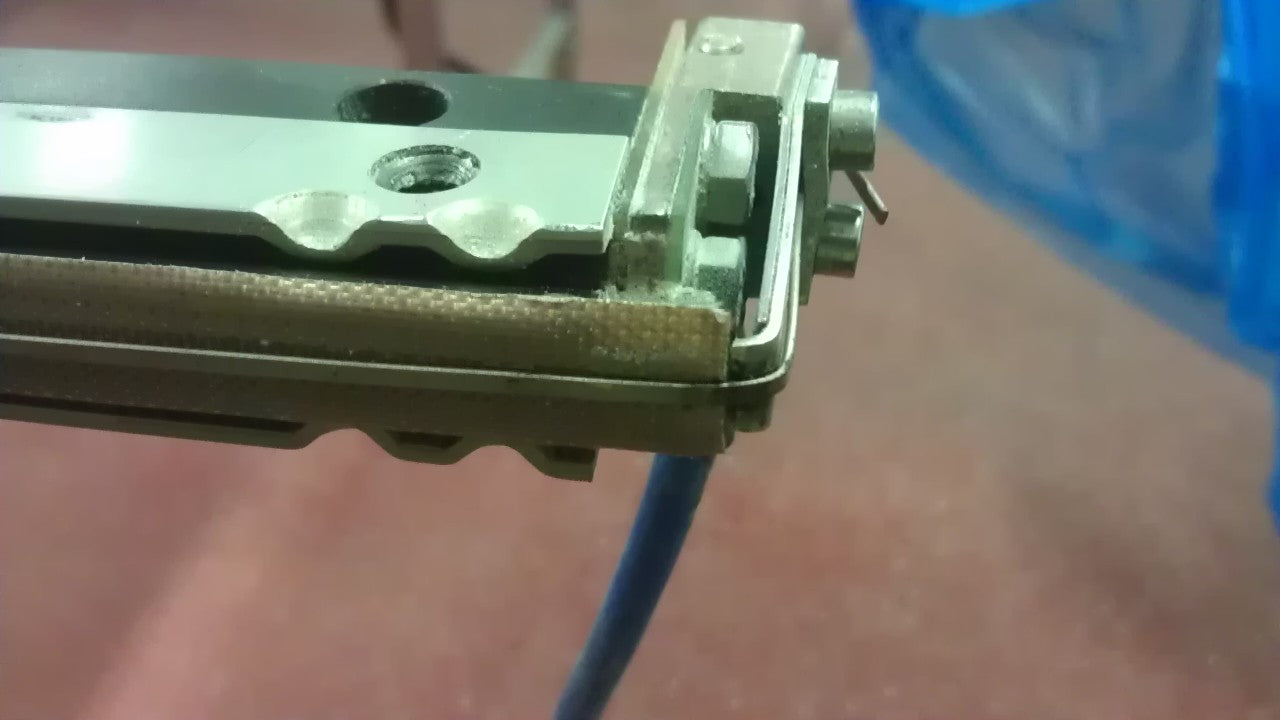

VS95TS

Seal Bar

The seal wire is tensioned by the flat spring on each end of the seal bar, but how much tension should be made when fitting a new wire. The wire should be fixed at one end and then tensioned at the other end giving approximately 1mm of gap at both ends, from the end of the curved plate to the bar.

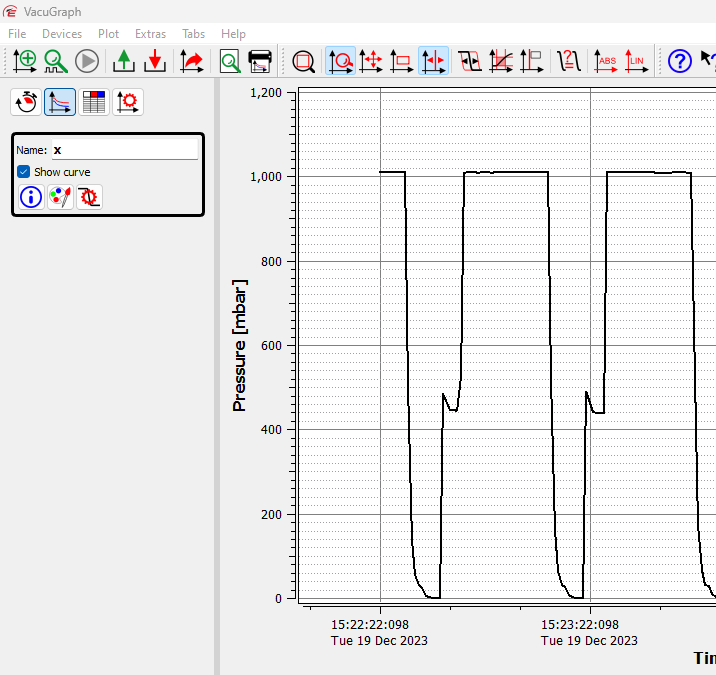

Performance reporting

Vacuum curves

Unsure of the performance of your equipment. We can check the vacuum levels of each chamber/hood, and see if improvement is needed. All part of the performance report

Lubrication

'Probably' the most important grease nipple.

That's the one - just above the oil lubrication unit. This greases the main bearing, and if that's not lubricated, it's two days work to replace ....... one bearing!!

VS95TS

A useful fault finding screen

Just how much inforation can be learnt from this screen.

1. Chamber leakage

2. Lowest achievable vacuum

and a lot more........?

VS95TS

Vacuum Valve

Pneumatically operated vacuum valve, x 2 on the VS95TS (x 1 on the VS95). Service yearly to ensure air does not bypass the X-ring seals.

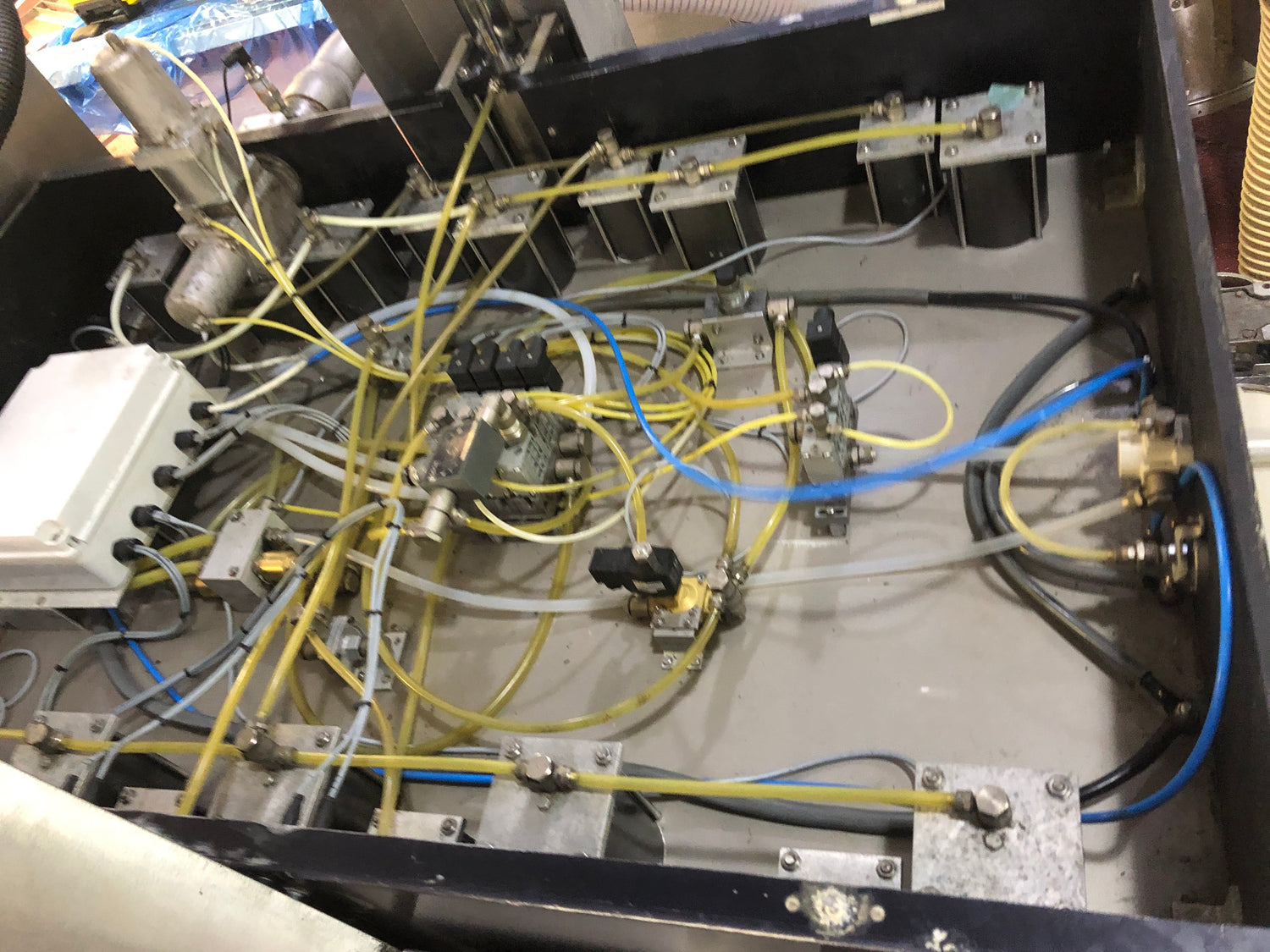

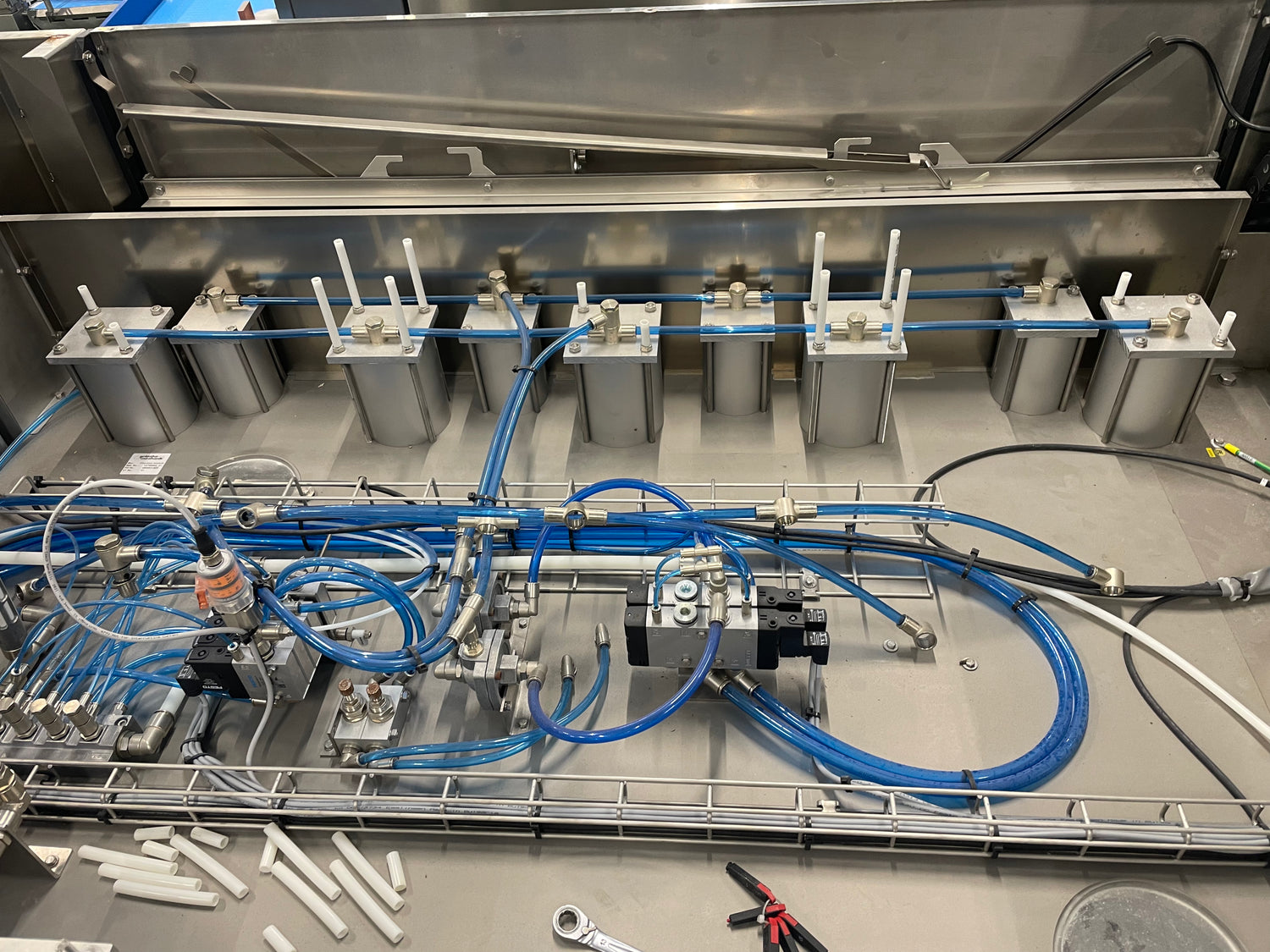

VS95TS

Sealing and pre-cutting cylinders

One side of the VS95TS, showing the sealing and pre-cutting cylinders. Pneumatically operated. Be aware, when removing the seal bar carrier mounting profile. These are under spring tension and the rod ends are not aligned unless the sealing cylinder is pneumatically operated. If you are unsure....please call Paul.

VS95TS

The broken one!

Why do we service. We check, dismantle, lubricate, replace worn parts, but occasionally we find ...the broken one. Luckily no damage to the cylinder lining, so a replacement was found.

VS95TS

Lubrication

Equipment within the food industry generally does not have oil lubrication within the pneumatic system - fair enough, we wouldn't want to exhaust oil into the atmosphere where food is being packed, but the problem now is we have moving parts that only get lubricated when serviced. No problem with regular servicing, so we would recommend these are removed, cleaned, checked for wear, lubricated and reassembled, at least annually.

VR Range of Machines

Slip Ring Assembly

Not looking in the best of order. The slip ring transfers the sealing current to each of the sealing bars in turn. Regular checking and cleaning will help keep these in good working order. If not, then they will need replacing. If you are unsure please contact us for more information.

STE98

What's wrong here

Water everywhere, and that is wasting energy. Minor adjustments to the water flow, and the pack shrink will still be the same, and cost less. And then you might ask - shouldn't the door be closed for the pump to be running. Normally yes, but it is possible to run the pump, with the side door open at low water temperatures. Want to know more.... a lot more?

Bearings

-

Shrink tunnel bearing

It doesn't look to bad from the front, and......

-

front and rear

and a wipe down seems to look in good order.....

-

and the back !

Service offerbut this bearing needed changing. Rough when turned by hand, rusting to the inner race, and signs of wear. Changed before the dreaded....collapse. Want our advise, change these every 6 months. PHL Maintenance fit these as part of our service offer.

Under cover

Safety 1

Sometimes it's easier to do the work lying down. But under a machine, where the LARGE chamber, which moves vertically down, could be a serious safety risk. These machines have a built in chamber locking device, that is (should be!) in the locked position when the chamber is up. This is not, and should not be seen as a suitable safety device for entry under the chamber. A clamp, that is attached to the machine should be put in place before any attempt, for what ever reason, is made to enter under the chamber. Are your operators, engineers trained to understand the safe operation of the equipment. Asking the question we're here to help.

Before undertaking any work on equipment you are unfamiliar with, please ensure you fully read the OEM manual for the equipment, and follow all safety instructions within.

Under cover

Safety 2

Yes, it was Paul having a break under the machine - honestly. But seriously, we take safety as our No.1 priority and here is the clamp mentioned in the previous picture, please make sure it's in place ......... but hang on a second, that chain is under the clamp -- that can't be right. Did you notice it before reading this. The securing chain under the clamp may cause a failure in the clamps operation, to hold the chamber up. Check and double check before entering the chamber. It's your, or someone elses life that's at risk. Yes this was corrected before Paul went for a lie down ;-)

Before undertaking any work on equipment you are unfamiliar with, please ensure you fully read the OEM manual for the equipment, and follow all safety instructions within.

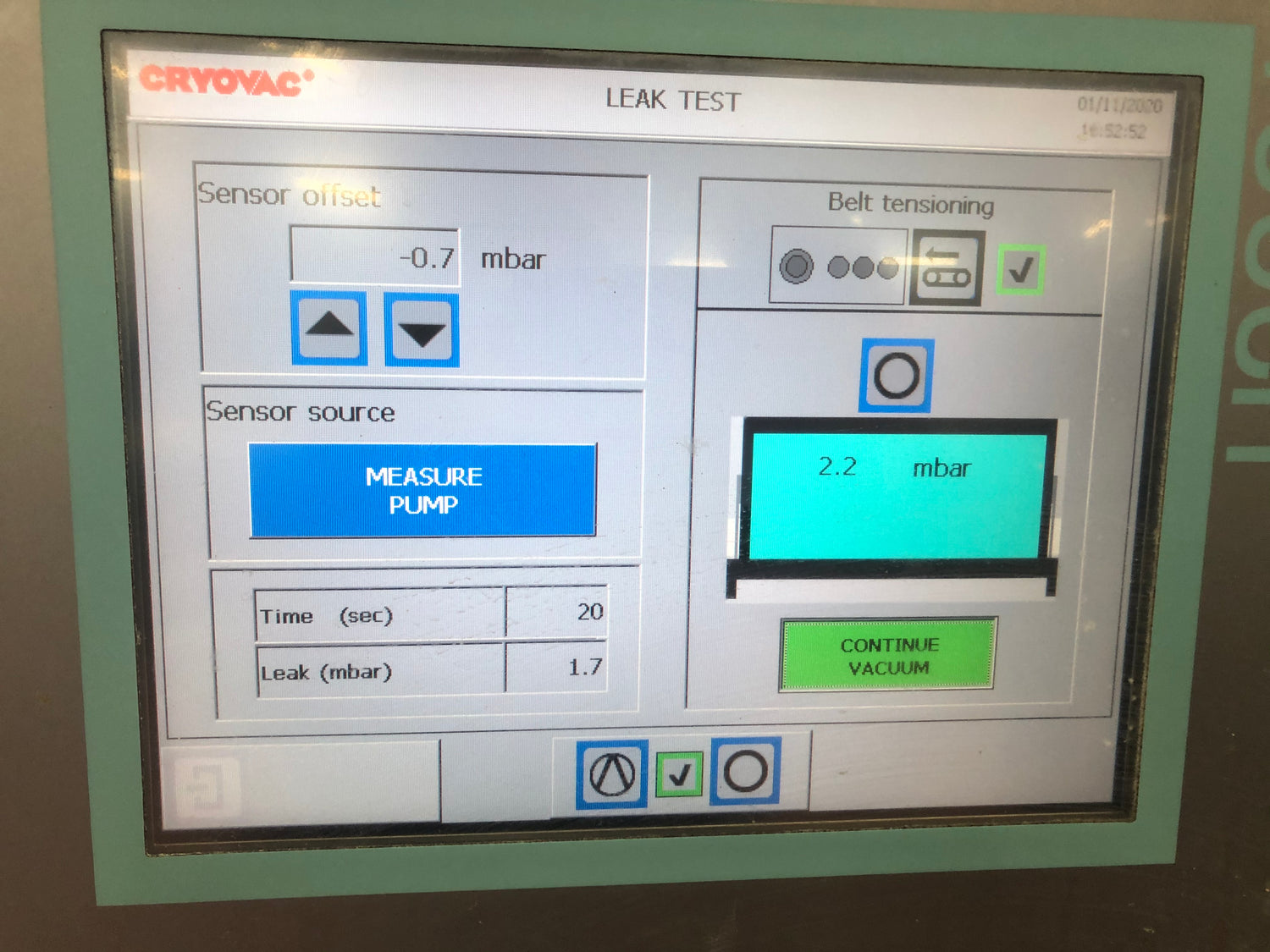

Vacuum

Job well done

Here at PHL Maintenance Ltd, we check before and after servicing, the vacuum levels within the equipment. Here we see a reading of 1 mbar (millibar) of air (gas if you wish) pressure. It doesn't get much better than that (OK '0' might the better, but we're happy with that). Want to know more about vacuum packaging equipment, vacuum levels for the food industry, the good, the bad, and the ugly about vacuum, give Paul a call...he love to talk vacuum.